Counterfeits with secure XRF gold analysis: In a world obsessed with gold’s gleam, the shadow of counterfeits looms large. From ancient times to the modern marketplace, the allure of gold has fueled a persistent problem—the creation of fake gold, costing economies billions. Traditional methods like acid testing fall short against increasingly sophisticated fakes. Enter X-ray fluorescence (XRF) technology, a game-changer in identifying the real deal from the cleverly crafted imitations. This deep dive explores how secure XRF analysis is revolutionizing gold authentication.

This article will dissect the science behind XRF, comparing different instruments and techniques, showing you how to interpret the data to pinpoint counterfeit gold. We’ll unravel the mysteries of XRF spectra, explore advanced applications, and even address the technology’s limitations, paving the way for future advancements in gold authenticity verification. Get ready to become a gold-detecting guru!

Introduction to Counterfeit Gold Detection

Source: made-in-china.com

The global gold market, a multi-billion dollar industry, is plagued by a significant problem: counterfeit gold. From intricately forged bars to deceptively plated jewelry, fraudulent gold items flood the market, causing substantial economic losses for consumers, businesses, and governments alike. This deception not only results in financial losses but also erodes trust in the integrity of the precious metals industry. The scale of the problem is vast, with counterfeit gold impacting everything from investment portfolios to the jewelry industry’s reputation.

The economic impact of counterfeit gold is multifaceted. Consumers suffer direct financial losses when purchasing fake gold, while businesses face reputational damage and loss of revenue. Furthermore, governments lose out on significant tax revenue due to the illicit nature of the counterfeit trade. The widespread availability of counterfeit gold undermines legitimate businesses and threatens the stability of the gold market as a whole.

Traditional gold testing methods, while useful in some instances, have inherent limitations. The acid test, for example, relies on visual observation of the reaction between gold and acid, a method that can be subjective and prone to error. Furthermore, these traditional techniques are often time-consuming and may not be able to detect sophisticated counterfeits that use advanced plating or alloying techniques. The need for a more accurate and efficient method of gold authentication is evident.

X-Ray Fluorescence (XRF) Technology in Precious Metal Analysis

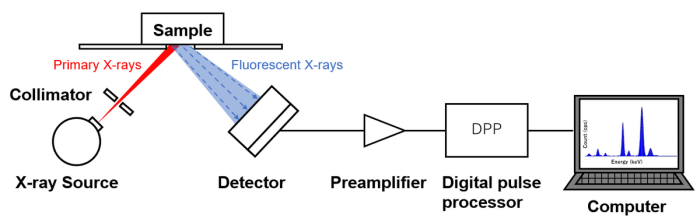

X-ray fluorescence (XRF) spectroscopy offers a rapid, non-destructive, and highly accurate method for analyzing the elemental composition of materials, including precious metals. Unlike traditional methods, XRF technology utilizes X-rays to excite the atoms in a sample, causing them to emit characteristic X-rays. The energy and intensity of these emitted X-rays are unique to each element, allowing for precise identification and quantification of the gold content in a sample. This technique provides a detailed elemental analysis, revealing not only the presence of gold but also the presence of any alloying metals or plating materials, enabling the detection of even the most sophisticated counterfeits. The speed and accuracy of XRF analysis make it an invaluable tool in combating the global problem of counterfeit gold.

Secure XRF Gold Analysis Techniques

Source: alicdn.com

X-ray fluorescence (XRF) spectrometry has revolutionized gold purity testing, offering a rapid, non-destructive method to determine the elemental composition of gold items. This technology allows for accurate identification of counterfeits and ensures fair valuation of genuine gold. Understanding the different XRF techniques and their applications is crucial for both professionals and consumers.

XRF instruments utilize the principle of exciting atoms within a sample using X-rays, causing them to emit secondary X-rays with characteristic energies. These energies correspond to specific elements, allowing for quantitative analysis of the gold’s purity and the presence of other metals.

Types of XRF Instruments for Gold Purity Testing

Several types of XRF instruments cater to different needs and budgets in gold purity testing. Handheld XRF analyzers offer portability and convenience, ideal for on-site testing and field applications. Benchtop XRF systems, on the other hand, provide higher precision and analytical capabilities, often preferred in laboratories for detailed analysis and quality control. Larger, more sophisticated laboratory-based systems may incorporate advanced features such as higher power X-ray tubes for increased sensitivity and better detection limits for trace elements.

Handheld XRF Analyzers vs. Laboratory-Based Systems

Handheld XRF analyzers are compact and easy to use, making them suitable for quick screening of gold items. They are typically less expensive than laboratory-based systems and require minimal sample preparation. However, their analytical precision and detection limits are generally lower compared to laboratory systems. Laboratory-based XRF spectrometers, conversely, offer superior precision, sensitivity, and the ability to analyze a wider range of elements and matrices. They are more suitable for complex samples and applications requiring high accuracy. The trade-off is their higher cost and the need for a controlled laboratory environment. For instance, a jeweler might use a handheld XRF analyzer to quickly assess the karat of a customer’s gold piece, while a precious metal refinery would rely on a laboratory-based system for precise compositional analysis before refining.

Calibration and Standardization Procedures for Accurate XRF Gold Analysis

Accurate XRF gold analysis hinges on proper calibration and standardization. Calibration involves creating a relationship between the measured X-ray intensities and the known concentrations of elements in a set of certified reference materials (CRMs). These CRMs, which are samples with precisely known compositions, are essential for establishing the instrument’s response to different gold alloys. Regular calibration ensures the accuracy and reliability of the measurements. Standardization procedures, often involving the use of standardless analysis software, help to minimize matrix effects and enhance the accuracy of the results. Regular checks with CRMs help maintain the accuracy of the analysis over time.

Step-by-Step Procedure for Using an XRF Analyzer to Test Gold Items

Before testing, ensure the XRF analyzer is properly calibrated and standardized. Always follow the manufacturer’s instructions for safe operation.

| Step Number | Procedure | Precautions | Expected Result |

|---|---|---|---|

| 1 | Turn on the XRF analyzer and allow it to warm up according to the manufacturer’s instructions. | Ensure the analyzer is properly grounded and in a stable position. | Analyzer ready for operation. |

| 2 | Clean the surface of the gold item to remove any dirt, grease, or other contaminants that might interfere with the analysis. | Use a soft, lint-free cloth and avoid abrasive materials. | Clean gold surface ready for analysis. |

| 3 | Position the gold item against the measurement window of the XRF analyzer. | Ensure good contact between the item and the window to minimize measurement error. | Item correctly positioned for analysis. |

| 4 | Initiate the analysis using the analyzer’s software. | Follow the software prompts and ensure the correct analysis parameters are selected. | Analysis initiated and data acquisition in progress. |

| 5 | Wait for the analysis to complete. The duration will depend on the instrument and the analysis parameters. | Avoid moving the item during the analysis. | Analysis complete. |

| 6 | Review the results displayed on the analyzer’s screen or in the software. The results will typically show the percentage of gold and other elements present in the sample. | Compare the results to the expected values based on the karat of the gold. | Quantitative analysis of gold purity and elemental composition. |

Interpreting XRF Data for Counterfeit Detection: Counterfeits With Secure Xrf Gold Analysis

X-ray fluorescence (XRF) spectrometry provides a powerful, non-destructive method for analyzing the elemental composition of materials, making it invaluable for identifying counterfeit gold. Understanding how to interpret the resulting data is crucial for accurate authentication. This section will delve into the key parameters within XRF spectra that reveal the purity of gold and the presence of any alloying elements, offering insights into distinguishing genuine articles from cleverly disguised imitations.

The XRF spectrum displays the intensity of X-rays emitted by each element present in the sample at specific energy levels. These peaks correspond to the characteristic X-rays emitted by the elements when excited by the X-ray beam. The intensity of each peak is directly proportional to the concentration of that element in the sample. This allows for a quantitative analysis of the gold’s purity and the identification of any adulterants.

Key Parameters in XRF Spectra

XRF spectra provide several key parameters for determining gold purity and identifying alloying elements. The most important parameter is the intensity of the gold (Au) L-alpha peak, which is directly proportional to the gold concentration. Other peaks represent other elements present, such as silver (Ag), copper (Cu), and platinum (Pt), which are often used in gold alloys. The relative intensities of these peaks, compared to the gold peak, reveal the alloy composition. The absence of significant peaks for other metals indicates high purity gold. Additionally, the presence of unexpected peaks suggests adulteration with other materials.

Examples of XRF Spectra for Pure Gold and Counterfeit Materials

To illustrate the differences, let’s consider hypothetical XRF spectra. Remember that the exact values will vary based on the equipment and testing conditions. However, the relative peak intensities will provide valuable insights.

- Pure Gold (24 Karat): The spectrum would show a dominant Au L-alpha peak with minimal or negligible peaks for other elements. Any minor peaks present would likely represent trace impurities naturally occurring in the gold ore.

- Gold-Silver Alloy (18 Karat): This spectrum would still show a significant Au L-alpha peak, but the intensity would be considerably lower than in pure gold. A prominent Ag L-alpha peak would also be present, indicating the presence of silver. The ratio of Au to Ag peaks will directly reflect the karatage.

- Counterfeit Material (Tungsten Core with Gold Plating): This example is more complex. A very weak Au L-alpha peak might be present, representing only the thin gold plating. A strong peak for tungsten (W) would be the defining feature, revealing the core material. Other elements from the plating process might also be present.

Differentiating Naturally Occurring Impurities from Intentionally Added Adulterants

The key to distinguishing between natural impurities and intentional adulterants lies in their concentration and combination. Naturally occurring impurities are usually present in trace amounts and consist of elements commonly associated with gold ores. Intentionally added adulterants, on the other hand, will typically be present in higher concentrations and may include elements not normally found in association with gold. For example, the presence of a high concentration of tungsten (W) would strongly suggest intentional adulteration, as tungsten is not a common component of gold alloys. A thorough analysis of the entire spectrum and comparison with known standards is crucial for this distinction.

Calculating Gold Karat from XRF Data

The karat of gold is determined by the proportion of pure gold in the alloy. XRF data allows for precise calculation of this proportion. For instance, if the XRF analysis shows that a sample contains 75% gold and 25% silver, the karat can be calculated as follows:

Karat = (Percentage of Gold / 24) * 24

In this example: Karat = (75/100) * 24 = 18 Karat

It’s important to note that this calculation is simplified. In reality, other alloying elements may also be present, requiring a more complex calculation taking into account the atomic weights of all constituent elements. However, the principle remains the same: the proportion of gold, as determined by the relative intensity of the Au L-alpha peak, is the key to determining the karat.

Advanced Applications of Secure XRF in Counterfeit Analysis

X-ray fluorescence (XRF) spectrometry has evolved beyond basic gold purity testing, becoming a powerful tool for dissecting the intricate world of counterfeit gold. Its ability to non-destructively analyze the elemental composition of materials allows for the identification of sophisticated counterfeits that might escape simpler detection methods. This section delves into the advanced applications of secure XRF in revealing the secrets hidden within seemingly genuine gold items.

Identifying Specific Types of Gold Counterfeits

Secure XRF excels at differentiating between genuine gold and its cleverly disguised imitations. For instance, gold-plated base metals, a common counterfeiting technique, can be easily unmasked. XRF analysis reveals the thin layer of gold plating atop a core of cheaper metals like copper, brass, or tungsten. The depth profiling capabilities of some advanced XRF instruments can even quantify the thickness of the gold plating, providing further evidence of counterfeiting. Similarly, filled gold, where a gold shell encases a less valuable metal core, is readily identifiable through XRF’s ability to pinpoint the elemental composition at various depths within the object. The distinct layering of gold and base metal is clearly revealed, leaving no room for ambiguity.

Comparison of XRF with Other Non-Destructive Testing Methods

While XRF stands out for its comprehensive analysis, it’s beneficial to compare its effectiveness against other non-destructive methods used for gold authenticity verification. Acid testing, a traditional method, involves applying a small amount of acid to the gold’s surface. A reaction indicates the presence of a non-gold alloy, but it can damage the item and only provides limited information about the overall composition. Visual inspection, relying on color, weight, and hallmark, is often the first step but easily fails against sophisticated counterfeits. XRF, in contrast, provides a detailed elemental profile, non-destructively and without damaging the object under examination.

Comparative Analysis of Counterfeit Detection Methods

| Method | Accuracy | Cost | Speed |

|---|---|---|---|

| XRF Analysis | High (identifies elemental composition) | Moderate to High (depending on equipment) | Moderate (analysis time varies) |

| Acid Testing | Low (only detects presence of alloys, not composition) | Low | Fast |

| Visual Inspection | Very Low (relies on subjective observations) | Very Low | Fast |

Case Study: Unmasking a Counterfeit Gold Bar, Counterfeits with secure xrf gold analysis

A seemingly pristine gold bar, presented for appraisal, showed all the hallmarks of authenticity: impressive weight, consistent color, and even a seemingly genuine hallmark. However, secure XRF analysis revealed a different story. The scan produced a detailed elemental profile showing a significant presence of tungsten throughout the bar, not just on the surface. This clearly indicated that the bar was not solid gold, but rather a tungsten core cleverly coated with a thin layer of gold to mimic the appearance and weight of a genuine gold bar. The XRF data provided irrefutable evidence of counterfeiting, protecting the appraiser and potential buyer from a significant financial loss.

Limitations and Future Trends in Secure XRF Gold Analysis

Source: horiba.com

While X-ray fluorescence (XRF) spectrometry offers a powerful, non-destructive method for gold analysis, its application in detecting sophisticated counterfeits isn’t without limitations. Understanding these limitations and exploring future advancements is crucial for maintaining the integrity of gold authentication processes. This section delves into the challenges XRF faces and the promising developments on the horizon.

Limitations of XRF in Detecting Sophisticated Counterfeits

Highly skilled counterfeiters employ increasingly intricate techniques to mimic the elemental composition of genuine gold. Standard XRF analysis, while effective for detecting simple alloys or plating, may struggle with these advanced counterfeits. For instance, sophisticated counterfeits might utilize a core of tungsten or other high-density metals coated with a thin layer of genuine gold, making it difficult for standard XRF to penetrate the surface and accurately assess the overall composition. The spatial resolution of some XRF instruments might also be insufficient to analyze microscopic variations in the gold layer’s thickness or composition, leading to misidentification. Furthermore, the presence of other elements in the sample matrix can interfere with the XRF signal, potentially leading to inaccurate results. The analytical depth of penetration can also limit the detection of very thin gold layers or complex multi-layered structures.

Potential Improvements and Advancements in XRF Technology

Several technological advancements promise to enhance XRF’s capabilities in counterfeit detection. Higher energy X-rays can penetrate deeper into the sample, revealing the underlying composition of more complex counterfeits. Improved spatial resolution, achieved through smaller spot sizes and advanced focusing optics, allows for more precise analysis of heterogeneous samples, such as those with microscopic layering. The development of portable and handheld XRF spectrometers allows for on-site analysis, eliminating the need to transport samples to a laboratory, thereby speeding up the authentication process. Furthermore, the integration of other analytical techniques, such as optical microscopy or Raman spectroscopy, with XRF can provide complementary information and enhance the overall accuracy of counterfeit detection.

The Role of Data Analysis and Machine Learning in Improving XRF Accuracy

The sheer volume of data generated by XRF analysis necessitates sophisticated data processing and analysis techniques. Machine learning (ML) algorithms can be trained on large datasets of both genuine and counterfeit gold samples to identify subtle patterns and variations that might be missed by human analysts. These algorithms can learn to recognize complex relationships between the XRF spectra and the authenticity of the sample, improving the accuracy and speed of counterfeit detection. This approach is particularly useful in dealing with complex counterfeits where the subtle variations in elemental composition or layering are difficult to discern visually. For example, an ML model could be trained to differentiate between a genuine gold item and a tungsten core with a thin gold plating based on subtle differences in the XRF spectral peaks and their intensities.

Hypothetical Advanced XRF System for Enhanced Counterfeit Detection

Imagine an advanced XRF system incorporating all the improvements mentioned above. This hypothetical system would feature a high-energy X-ray source capable of penetrating thick layers of material, a micro-focus X-ray beam for high spatial resolution analysis, and an integrated optical microscope for visual inspection of the sample surface. The system would also include a sophisticated data processing unit employing advanced ML algorithms to analyze the XRF spectra and provide a rapid, accurate assessment of the gold’s authenticity. This system could potentially incorporate automated sample handling and reporting features, further streamlining the analysis process. The benefits would be a significant reduction in false positives and negatives, leading to more reliable gold authentication and a reduction in the economic losses associated with gold counterfeiting. This system would represent a significant advancement in gold authentication technology, offering a robust and reliable method for detecting even the most sophisticated counterfeits.

Outcome Summary

So, there you have it – a comprehensive look at how secure XRF gold analysis is fighting the good fight against counterfeit gold. From understanding the technology to interpreting its results, we’ve covered the essentials. While XRF isn’t a foolproof solution, its accuracy and speed make it an invaluable tool in the ongoing battle against deception. As technology continues to evolve, expect even more precise and efficient methods to emerge, ensuring that the shine of genuine gold remains untarnished.